The Craftsman 1/2 HP Garage Door Opener offers reliable performance with a durable belt drive, ensuring quiet operation and smooth functionality for residential use․

1․1 Overview of the Product

The Craftsman 1/2 HP Garage Door Opener is a reliable and efficient solution for residential garage door automation․ Designed for smooth operation, it features a durable belt drive system, ensuring quiet performance and longevity․ Compatible with most standard garage doors, it offers convenient control via wireless remotes and smartphone integration through the Craftsman app․ This opener is built for seamless functionality, providing easy access and enhanced security for homeowners․ It is designed to meet residential needs with consistent and dependable performance․

1․2 Key Features and Benefits

The Craftsman 1/2 HP Garage Door Opener features a powerful yet quiet belt drive system, ensuring smooth and reliable operation․ It includes wireless remote control, smartphone app integration, and motion detection for added convenience and security․ Designed for energy efficiency, it complies with UL 325 safety standards, offering peace of mind for homeowners․ Its durable construction and advanced features make it a practical choice for seamless garage door automation and long-term performance․

Safety Precautions and Warnings

Always disable locks before installation and operation․ Ensure the opener operates at 120V, 60Hz․ Secure the header bracket to structural supports․ Read and follow all safety rules and operating instructions before first use․ Fasten the manual near the garage door for easy reference․

2․1 General Safety Guidelines

Always disable locks before installation and operation․ Ensure the opener operates at 120V, 60Hz․ Secure the header bracket to structural supports․ Read and follow all safety rules and operating instructions before first use․ Fasten the manual near the garage door for easy reference․ Test the garage door balance annually․ Keep the area clear during installation and operation․ Avoid operating the door if it is damaged or unbalanced․ Use a wood screw or nail to hold locks in the open position during installation․

2․2 Important Warnings Before Installation

Before installation, ensure the garage door is balanced and free from damage․ Disable all locks to prevent interference․ Verify the opener operates at 120V, 60Hz․ Secure the header bracket to structural supports only․ Avoid installing near flammable materials․ Test the door balance annually․ Do not operate if the door is unbalanced or damaged․ Fasten the manual near the garage door for reference․ Ensure the area is clear during installation․ Follow all instructions carefully to avoid malfunctions․

2․3 Compliance with UL 325 Regulations

The Craftsman 1/2 HP Garage Door Opener complies with UL 325 standards, ensuring enhanced safety and reliability․ These regulations require features like automatic reversal and proper sensing to prevent accidents․ The opener must be installed, operated, and maintained as per the manual to meet these standards․ Compliance is effective January 1, 1993, and ensures the opener operates safely under normal conditions․ Always follow UL guidelines for installation and testing to maintain compliance and ensure user safety․

Installation Instructions

The Craftsman 1/2 HP Garage Door Opener requires careful assembly and installation․ Follow the manual for rail system assembly, header bracket placement, and door arm connection․

3․1 Assembly of the Rail System

Assembling the rail system is a critical step in installing the Craftsman 1/2 HP Garage Door Opener․ Begin by attaching the rail sections together, ensuring proper alignment and secure connections․ Use the provided hardware to tighten all joints firmly․ Next, mount the trolley and attach it to the rail, ensuring it moves smoothly․ Always follow the manufacturer’s instructions for assembly and installation․ Make sure the rail system is level and properly aligned with the garage door to ensure safe and efficient operation․ Refer to the manual for detailed diagrams and step-by-step guidance․

3․2 Header Bracket Location and Installation

Locate the header bracket by identifying the center of the garage door opening․ Ensure the bracket is installed on a sturdy structural support, such as a ceiling joist or header beam․ Use a level to confirm the bracket is properly aligned and secure it with the provided screws․ Double-check the alignment to ensure the rail system will move smoothly․ Refer to the manual for specific measurements and diagrams to ensure accurate installation and proper functionality of the garage door opener․

3․3 Connecting the Door Arm to the Trolley

Align the door arm with the trolley by sliding it onto the clevis pin․ Secure it with the provided clip or nut, ensuring it clicks firmly into place․ Adjust the chain tension if necessary to maintain proper alignment․ Test the connection by gently pulling on the arm to ensure it’s sturdy․ Always ensure the garage door is fully closed and locks are disengaged before connecting․ Refer to the manual for specific diagrams and torque specifications to ensure a secure and proper installation․

Troubleshooting Common Issues

Identify common problems like the door not opening, irregular operation, or strange noises․ Check power supply, chain tension, and obstructions․ Refer to the manual for detailed solutions․

4․1 Identifying Common Problems

The Craftsman 1/2 HP Garage Door Opener may encounter issues such as the door not opening, irregular operation, or strange noises․ These problems can often be traced to a malfunctioning remote, misaligned sensors, or a faulty capacitor․ Additionally, issues like the door reversing or the opener lights blinking indicate specific errors․ It’s important to consult the troubleshooting section of the manual to identify and address these problems effectively․

4․2 Resetting the Garage Door Opener

Resetting the Craftsman 1/2 HP Garage Door Opener can resolve issues like erratic behavior or failed remote programming․ To reset, unplug the opener from the power source, wait 10 seconds, and reconnect it․ This soft reset clears temporary glitches․ After resetting, reprogram the remote controls and test the door operation․ If problems persist, refer to the troubleshooting guide or consider more advanced diagnostics, such as checking sensors or the capacitor․

4․3 Checking and Replacing the Capacitor

To check the capacitor, disconnect power and locate it near the motor․ Discharge it by shorting the terminals with an insulated screwdriver․ Use a multimeter to test voltage levels; if faulty, replace it with a compatible model․ Ensure the new capacitor matches the voltage rating specified in the manual․ Proper replacement ensures reliable operation and prevents motor failure․ Always follow safety precautions when handling electrical components․

Programming the Remote Control

Press the learn button on the opener, enter your code, and synchronize the remote․ Test functionality to ensure proper operation and secure connection to the garage door opener․

5․1 Step-by-Step Programming Guide

Locate the “Learn” button on the garage door opener, typically found near the antenna․ Press and release it to enter programming mode․ The LED will flash, indicating readiness․

Within 30 seconds, press and hold the remote control button you wish to program until the opener’s LED flashes again․

Release the button and test the remote to ensure proper functionality․ Repeat for additional remotes if needed․

Ensure all remotes are synced and functioning correctly before completing the setup․ This ensures secure and reliable operation of your garage door opener․

5․2 Syncing Multiple Remotes

To sync multiple remotes with your Craftsman 1/2 HP Garage Door Opener, start by pressing the “Learn” button on the opener until the LED flashes․ This initiates the syncing process․ Next, press and hold the desired button on the first remote until the LED flashes again, indicating successful syncing․ Repeat this process for additional remotes, ensuring each is synced individually․ After syncing, test all remotes to confirm they operate the opener correctly․ This ensures seamless control from multiple devices․

5․3 Troubleshooting Remote Control Issues

If your remote control isn’t working, start by replacing weak or dead batteries․ Ensure the remote is synced correctly with the opener by pressing the “Learn” button and holding the remote button until the LED confirms syncing․ Check for interference from other devices and test the remote near the opener․ If issues persist, reset the opener by unplugging it, waiting 30 seconds, and plugging it back in․ This often resolves connectivity problems with the remote control system․

Maintenance and Care

Regularly inspect and clean the garage door opener to ensure smooth operation․ Lubricate moving parts annually, and check for wear on belts or chains․ Schedule maintenance to prevent malfunctions and extend the opener’s lifespan․

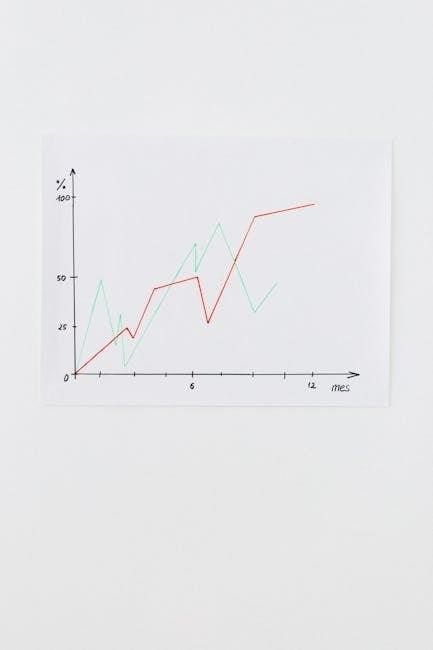

6․1 Regular Maintenance Schedule

Perform routine maintenance every 6-12 months to ensure optimal performance․ Lubricate moving parts annually, inspect chains or belts for wear, and tighten loose screws․ Check safety sensors monthly and test door balance regularly․ Refer to the manual for specific lubrication points and adjustment instructions․ Clean the opener’s exterior and ensure all components are free from debris․ Schedule professional servicing if issues persist beyond basic maintenance․

6․2 Lubricating Moving Parts

Lubricate the garage door opener’s moving parts, such as chains, hinges, and rollers, every 6-12 months․ Use a silicone-based spray lubricant to ensure smooth operation and reduce wear․ Apply a small amount to each moving component, avoiding over-lubrication, which can attract dust․ Wipe off excess lubricant with a clean cloth․ Regular lubrication prevents squeaking and extends the lifespan of the opener․ Refer to the manual for specific lubrication points and instructions․

6․3 Cleaning the Garage Door Opener

Regular cleaning ensures optimal performance and longevity of your Craftsman 1/2 HP Garage Door Opener․ Use a soft cloth and mild detergent to wipe down the motor, rail, and other visible components․ Avoid harsh chemicals or abrasive materials that may damage finishes․ Clean the sensor eyes to maintain proper alignment and functionality․ Dust and debris can accumulate, so wipe the rail and moving parts with a dry cloth periodically․ Refer to the manual for specific cleaning guidelines to keep your opener in prime condition․

Understanding the Manual

The manual provides a comprehensive guide to installing, operating, and maintaining your Craftsman 1/2 HP Garage Door Opener, ensuring safe and effective use of the device․

7․1 Navigating the Manual Sections

The manual is organized into clear sections, making it easy to locate specific information․ Key areas include installation, safety precautions, operation, and troubleshooting․ Each section is detailed with step-by-step instructions and visual guides to ensure clarity․ Users can quickly find relevant content using the table of contents or index․ The manual also includes a glossary for technical terms and reference pages for maintenance schedules․ This structured approach helps users navigate efficiently and understand their garage door opener’s functionality and care requirements․

7․2 Important Pages to Reference

Key sections include the safety precautions, installation guide, and troubleshooting tips․ Pages 12-15 detail the assembly process, while pages 18-20 cover operation and maintenance․ The troubleshooting section (pages 22-24) addresses common issues like capacitor replacement; Refer to page 5 for warranty information and page 9 for compliance with UL 325 regulations․ These sections ensure proper installation, safe operation, and effective maintenance of your garage door opener․

7․3 Glossary of Terms

This section defines key terms related to the Craftsman 1/2 HP Garage Door Opener․ HP (Horsepower) measures the opener’s power․ UL 325 refers to safety standards for automatic door openers․ The trolley moves along the rail, operating the door․ A capacitor stores energy for motor startup․ The header bracket secures the opener to the ceiling, while the door arm connects the trolley to the door․ Understanding these terms aids in proper installation and maintenance․

Operation Instructions

Operate your Craftsman 1/2 HP opener via remote, wall button, or smartphone app for smooth, quiet door movement․ Emergency release ensures manual operation during power outages․

8․1 Opening and Closing the Garage Door

Press the remote control or wall button to open/close the door․ For manual operation, pull the emergency release handle․ Ensure the door is fully closed before locking․ Always test the safety reversal feature after adjustments․ Refer to the manual for programming or troubleshooting guidance․ Regular maintenance ensures smooth operation and longevity of the system․

8․2 Using the Emergency Release

The emergency release handle allows manual operation during power outages․ Pull the handle downward to disengage the trolley from the door․ Ensure the garage door is fully closed before re-engaging․ Always disable locks before use to prevent damage․ Test the door manually after disengaging to ensure proper balance․ Follow safety guidelines in the manual for secure operation․ Regular checks ensure smooth functionality and safety compliance․ Proper use extends the system’s lifespan and ensures reliable performance․

8․3 Adjusting the Door Balance

Proper door balance ensures smooth operation and reduces strain on the opener․ Check the door’s alignment and spring tension annually․ If the door sags or feels heavy, adjust the springs or cables․ Always disconnect power and engage the emergency release before adjustments․ Refer to the manual for specific instructions․ Test the door manually after adjustments to ensure balance and safety․ Regular checks prevent wear and tear, ensuring optimal performance and longevity of the system․

Compatible Models and Parts

The Craftsman 1/2 HP Garage Door Opener is compatible with multiple Craftsman models, including CMXEOCG231 and CMXEOCG472․ Replacement parts like capacitors and remotes are available through Sears Parts Direct, ensuring easy maintenance and upgrades․

9․1 List of Compatible Craftsman Models

The Craftsman 1/2 HP Garage Door Opener is compatible with several models, including the CMXEOCG231, CMXEOCG472, and 139․53985DM․ These models share similar features such as smartphone app integration and motion detection․ Additional compatible models include 139․53975SRT1 and 139․53962SRT1, ensuring versatility for various residential setups․ For a full list, refer to the official Craftsman website or Sears Parts Direct, which provides detailed compatibility charts and replacement parts․

9․2 Recommended Replacement Parts

Key replacement parts for the Craftsman 1/2 HP Garage Door Opener include the capacitor, belt, remote control, and logic board․ Sears Parts Direct offers genuine components like the capacitor (EPCOS 89uF 250V) and motor start capacitors․ Additionally, compatible belts and remote controls ensure smooth operation․ For specific models like 139․53975SRT1 and 139․53962SRT1, refer to the official Craftsman website or the provided manuals for exact part numbers and diagrams to simplify the replacement process․

9․3 Where to Find Parts and Manuals

Replacement parts and manuals for the Craftsman 1/2 HP Garage Door Opener can be found on the Sears Parts Direct website or the official Craftsman website․ Sears Parts Direct provides detailed part diagrams and compatibility information, while Craftsman offers downloadable PDF manuals for specific models․ Additionally, the manual itself includes a list of compatible models and their respective part numbers, making it easier to locate the correct components for your opener․

Warranty Information

The Craftsman 1/2 HP Garage Door Opener is backed by a comprehensive warranty covering parts and labor for a specified period, ensuring customer satisfaction and product reliability․

10․1 Coverage and Duration

The Craftsman 1/2 HP Garage Door Opener warranty provides comprehensive coverage for parts and labor, ensuring durability and reliability․ The motor is typically covered for 10 years, while other components, such as the belt or chain, are covered for 5 years․ This warranty underscores Craftsman’s commitment to quality, offering peace of mind for homeowners․ Specific terms and conditions may vary, so reviewing the warranty document is essential for full understanding․

10․2 Filing a Warranty Claim

To file a warranty claim for the Craftsman 1/2 HP Garage Door Opener, review the warranty document to ensure eligibility․ Contact Sears Parts Direct for assistance with parts and diagrams․ Provide proof of purchase and a detailed description of the issue․ Claims can be submitted online or by phone to customer service․ Ensure all repairs are performed by authorized technicians to maintain warranty validity․ Prompt processing helps resolve issues efficiently, upholding Craftsman’s commitment to customer satisfaction․

10․4 Exclusions and Limitations

The warranty excludes damage from misuse, neglect, or improper installation․ Normal wear and tear, such as battery degradation in remotes, is not covered․ Repairs or modifications by unauthorized technicians void the warranty․ Damage caused by third-party parts or failure to follow manual instructions is also excluded․ The warranty does not cover consequential damages or labor costs for repairs․ Ensure all claims adhere to these terms to maintain coverage under the Craftsman warranty program․

Advanced Features

The Craftsman 1/2 HP Garage Door Opener features smartphone app integration, motion detection, and energy-efficient operation, enhancing security, convenience, and performance for modern homeowners․

11․1 Smart Phone App Integration

The Craftsman 1/2 HP Garage Door Opener seamlessly integrates with smartphone apps, allowing users to monitor and control their garage door remotely․ Through the app, homeowners can receive notifications when the door is opened or closed, grant access to guests, and schedule operations․ This feature enhances convenience and security, enabling real-time monitoring and management from anywhere․ Compatibility with both iOS and Android ensures universal accessibility, making it a modern solution for smart home integration․

11․2 Motion Detection and Security Features

The Craftsman 1/2 HP Garage Door Opener includes advanced motion detection and security features to enhance home protection․ The system alerts users of unexpected movements near the garage door, ensuring unauthorized access is detected promptly․ Additionally, the opener features automatic lighting activation upon motion sensing, deterring potential intruders․ With encrypted remote control signals and secure smartphone app integration, this opener provides robust security measures to safeguard your garage and home, offering peace of mind for homeowners․

11․3 Energy Efficiency and Savings

The Craftsman 1/2 HP Garage Door Opener is designed with energy efficiency in mind, featuring a powerful yet low-consumption motor that minimizes energy usage․ Its advanced belt-drive system reduces operational noise while maintaining optimal performance․ The opener is compatible with smart home systems, allowing users to monitor and control energy consumption remotely․ Additionally, it includes an Energy Star certification, ensuring it meets strict energy-saving standards․ Automatic LED lighting and adjustable timers further enhance energy efficiency, making it a cost-effective solution for homeowners․

User FAQs

Common questions include troubleshooting issues, remote programming, and maintenance tips․ The manual provides detailed solutions for these topics, ensuring seamless operation and optimal performance of the opener․

12․1 Most Common Questions

Users often inquire about troubleshooting common issues like door balance, remote programming, and capacitor replacement․ They also ask about compatibility with smart devices, maintenance schedules, and warranty details․ Many seek guidance on installing the opener, syncing multiple remotes, and understanding error codes․ Additionally, questions about energy efficiency, safety features, and proper lubrication of moving parts are frequent․ These topics are addressed in detail to ensure smooth operation and optimal performance of the Craftsman 1/2 HP garage door opener․

12․2 Answers to Technical Queries

Technical queries often focus on troubleshooting, such as capacitor replacement and remote programming․ The opener’s capacitor can be replaced by disconnecting power, locating the capacitor, and installing a new one․ Remote programming involves syncing frequencies with the opener․ Users also inquire about compatibility with smart devices and UL 325 compliance․ Additionally, questions about motor maintenance, chain tension adjustment, and door balance correction are common․ These queries are addressed with step-by-step solutions for optimal functionality․

12․3 Tips for Optimal Performance

For optimal performance, regularly lubricate moving parts and ensure proper alignment of the door arms․ Clean the opener’s exterior and rails to prevent debris buildup․ Check and tighten loose screws periodically․ Maintain a balanced door to reduce strain on the motor․ Replace worn-out parts promptly and avoid overloading the opener․ Following these tips ensures smooth, quiet operation and extends the lifespan of your Craftsman 1/2 HP garage door opener․

The Craftsman 1/2 HP Garage Door Opener provides reliable performance, ease of use, and durability․ Proper maintenance and adherence to the manual ensure optimal functionality and longevity․

13․1 Final Thoughts on the Craftsman 1/2 HP Garage Door Opener

The Craftsman 1/2 HP Garage Door Opener is a reliable choice for homeowners, offering smooth and quiet operation․ Its durable design and user-friendly features make it a practical solution for daily use․ With compatibility across various garage door types, it provides consistent performance․ The integration of smart technology and safety features enhances convenience and security․ Overall, it is a solid investment for those seeking a balance of power, efficiency, and modern functionality․

13․2 Encouragement for Proper Usage and Maintenance

Proper usage and regular maintenance are essential to extend the lifespan of your Craftsman 1/2 HP Garage Door Opener․ Ensure to lubricate moving parts annually, clean components, and inspect for wear․ Always follow safety guidelines and refer to the manual for specific instructions․ By adhering to these practices, you’ll enjoy reliable performance, enhanced security, and optimal functionality for years to come․