The Hoover SteamVac SpinScrub is a powerful deep cleaner designed for effective carpet and upholstery cleaning. It features SpinScrub technology for thorough stain removal and versatility across surfaces.

1.1 Overview of the Hoover SteamVac SpinScrub Carpet Cleaner

The Hoover SteamVac SpinScrub Carpet Cleaner is a versatile and efficient deep cleaning solution designed for carpets, upholstery, and hard floors. It utilizes advanced SpinScrub technology, which employs rotating brushes to gently yet effectively remove stains and embedded dirt. The cleaner is equipped with heated cleaning capabilities to enhance stain removal and sanitize surfaces. Its lightweight design and ergonomic controls make it easy to maneuver and operate. The SteamVac SpinScrub is ideal for both small spills and deep cleaning tasks, offering a practical solution for maintaining clean and hygienic surfaces. Regular maintenance, such as cleaning filters and emptying tanks, ensures optimal performance. This cleaner is a reliable choice for homeowners seeking a comprehensive cleaning tool.

1.2 Key Features of the SteamVac SpinScrub

The SteamVac SpinScrub boasts several key features that make it a standout cleaning solution. Its SpinScrub technology uses rotating brushes to deeply penetrate carpets and upholstery, effectively removing tough stains. The cleaner also includes a heated cleaning option, which helps sanitize surfaces and enhance stain removal. Additionally, it features a large, easy-to-fill clean solution tank and a built-in water heater for consistent cleaning performance. The lightweight design and ergonomic handle provide ease of use, while the adjustable settings allow for customization based on cleaning needs. These features collectively ensure a thorough and efficient cleaning experience, making the SteamVac SpinScrub a versatile tool for various surfaces.

1.3 Importance of Following the Instruction Manual

Following the instruction manual for the Hoover SteamVac SpinScrub is essential for safe and effective operation; The manual provides critical information on assembly, usage, and maintenance, ensuring optimal performance and longevity of the cleaner. It outlines safety precautions to prevent accidents, such as electrical hazards or improper use on certain surfaces. Adhering to the guidelines helps avoid damage to the machine or cleaned surfaces. Additionally, the manual includes troubleshooting tips for common issues, which can save time and effort. Ignoring the instructions may lead to suboptimal cleaning results or even void the warranty. By following the manual, users can ensure a safe, efficient, and satisfactory cleaning experience while maintaining the product’s durability.

Safety Precautions

The Hoover SteamVac SpinScrub requires adherence to safety guidelines for optimal operation. Use indoors only, avoid immersion, and do not use as a dry vacuum. Always follow safety instructions to ensure safe and efficient cleaning experiences.

2.1 General Safety Warnings

Always follow general safety precautions when using the Hoover SteamVac SpinScrub to ensure safe and effective operation. Use the cleaner indoors only and avoid immersing it in water. Do not use it as a dry vacuum cleaner, as this may damage the unit or pose a safety risk. Ensure the upholstery fabric is marked with a “W” or “S/W” cleaning code before cleaning. Avoid using the SteamVac on hardwood floors unless specified. For liquid spills, only clean up amounts of 1 gallon or less. Keep children and pets away during operation, and never leave the machine unattended while it is in use. Proper usage ensures both safety and optimal cleaning performance.

2.2 Electrical Safety Guidelines

To ensure safe operation of the Hoover SteamVac SpinScrub, adhere to electrical safety guidelines. Avoid exposing the cleaner to water or moisture, as this can lead to electrical hazards. Use the machine only on indoor surfaces and never submerge it in water. Ensure the power cord is not damaged or frayed, and avoid overloading electrical outlets. Always plug the cleaner into a properly grounded outlet rated for its voltage requirements. Do not use the machine near water sources, such as bathtubs or swimming pools. If the cleaner malfunctions, unplug it immediately and contact an authorized service center for repairs. Follow these guidelines to prevent electrical shock or fire risks and maintain safe functionality.

2.3 Precautions for Proper Use

Always follow precautions for proper use of the Hoover SteamVac SpinScrub to ensure safe and effective cleaning. Before cleaning, check the fabric or surface to ensure it is compatible with the cleaner. For upholstery, only use the cleaner on fabrics marked with a “W” or “S/W” cleaning code. Avoid using the SteamVac on hardwood floors, as it may damage the surface. Do not use the cleaner as a dry vacuum, as it is designed for wet cleaning only. Never pick up large amounts of water or liquids, as this can damage the machine. Keep the cleaner away from children and pets during operation. Always refer to the instruction manual for specific guidelines tailored to your cleaning needs.

Assembly and Parts

Proper assembly is crucial for safe and effective use of the Hoover SteamVac SpinScrub. Familiarize yourself with all parts and components before use.

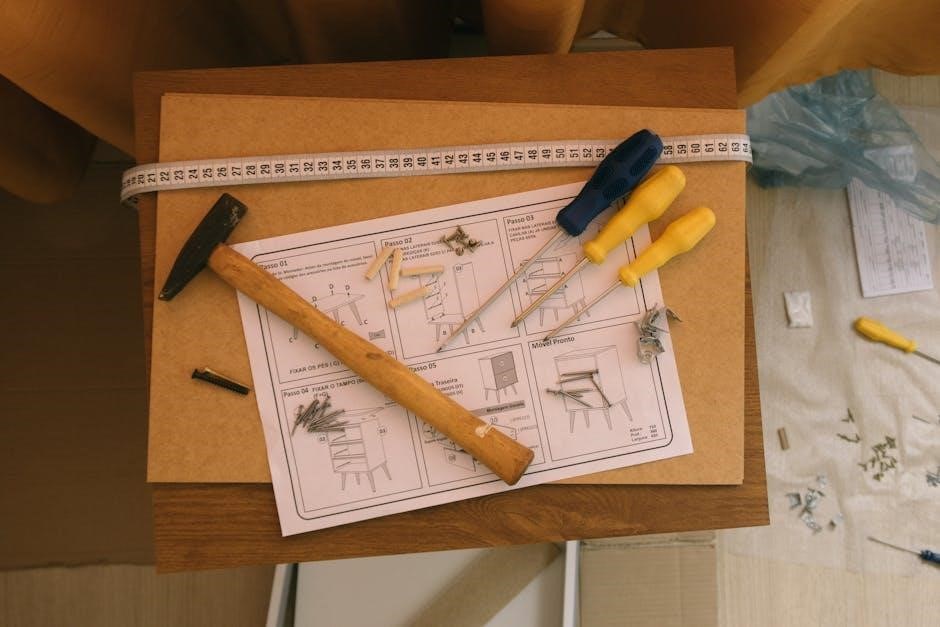

3.1 Unpacking and Inventory of Parts

When you unpack your Hoover SteamVac SpinScrub, carefully inspect all components to ensure nothing is damaged. The box should include the main unit, SpinScrub brushes, clean solution tank, recovery tank, upholstery tool, and crevice tool. Check for any missing or damaged parts by referring to the parts list in the manual. Familiarize yourself with each component’s purpose to ensure proper assembly and operation. If any parts are missing or damaged, contact Hoover customer support immediately. Proper inventory ensures all necessary tools are available for efficient cleaning and maintenance. Always refer to the manual for guidance on identifying and organizing parts effectively.

3.2 Step-by-Step Assembly Instructions

Begin by unpacking all components and verifying no parts are damaged. First, attach the recovery tank to the main unit by aligning the hooks and securing it firmly. Next, insert the SpinScrub brushes into the brush compartment, ensuring they click into place. Attach the clean solution tank by sliding it into the designated slot on the top of the machine. Connect the upholstery tool and crevice tool to their respective holders for easy access. Finally, plug in the power cord and ensure all parts are securely locked. Refer to the manual for visual guides to confirm proper assembly. Double-check that all connections are tight and no parts are loose before use.

3.4 Identifying Key Components

The Hoover SteamVac SpinScrub features several essential components designed for efficient cleaning. The clean solution tank holds the cleaning detergent and water mixture, while the recovery tank collects dirty water and debris. The SpinScrub brushes are located on the bottom and rotate to agitate carpets. The handle includes controls for solution dispersion and suction. Additional tools like the upholstery tool and crevice tool are stored on the machine for versatility. The foot pedal allows for hands-free operation, and the tank lid provides access for refilling or emptying. Understanding these components ensures proper use and maintenance of the SteamVac SpinScrub, optimizing its performance for various cleaning tasks.

Operating the SteamVac SpinScrub

Operating the Hoover SteamVac SpinScrub involves preparing the machine, filling the solution tank, and using the SpinScrub brushes for effective cleaning on carpets, upholstery, and hard floors.

4.1 Preparing for Cleaning

Before using the Hoover SteamVac SpinScrub, ensure the area is clear of clutter and large debris. Always check the surface type and cleaning code for upholstery to avoid damage. For carpets, vacuum thoroughly to remove loose dirt. Pre-treat stains or high-traffic areas with a cleaning solution before deep cleaning. Assemble the machine according to the manual, ensuring all parts are securely attached. Fill the clean solution tank with Hoover-recommended detergent for optimal results. Avoid using the SteamVac on hardwood floors or surfaces that cannot be exposed to moisture. Always refer to the manual for specific instructions to ensure safe and effective cleaning.

4.2 Filling the Clean Solution Tank

To fill the clean solution tank on your Hoover SteamVac SpinScrub, start by using Hoover-recommended Carpet/Upholstery Detergent for optimal cleaning results. Locate the clean solution tank, typically the upper tank, and remove it from the machine. Fill the tank with warm water to the recommended level, ensuring not to exceed the maximum fill line. Add the appropriate amount of detergent as specified in the manual. Avoid overfilling, as this may cause leaks or poor performance. Once filled, securely reattach the tank to the machine, making sure it clicks into place. Always refer to the manual for specific guidelines on solution ratios and tank capacity to ensure proper function and avoid damage to the machine.

4.3 Using the SpinScrub Technology

The SpinScrub technology in the Hoover SteamVac SpinScrub is designed to provide a deep and effective clean. To use this feature, ensure the machine is set to the appropriate mode for your surface type, such as carpet or hard floors. Activate the SpinScrub brushes by pressing the designated button, which will begin rotating the brushes at a high speed. Slowly move the machine forward and backward, allowing the brushes to agitate the carpet fibers or hard surface. Use overlapping passes to cover the entire area thoroughly. For tough stains, pause and let the brushes work for a few seconds before continuing. This method ensures efficient cleaning and helps maintain the longevity of your floors. Always follow the manual’s guidelines for specific surface recommendations to avoid damage.

4.4 Cleaning Different Surfaces (Carpet, Upholstery, Hard Floors)

The Hoover SteamVac SpinScrub is versatile for various surfaces. For carpets, use the SpinScrub brushes to deeply agitate fibers, removing embedded dirt. Adjust the cleaner to the appropriate mode for carpet thickness. For upholstery, attach the provided tool and ensure the fabric is labeled with a “W” or “S/W” cleaning code. Gently clean in sections, avoiding excessive moisture. On hard floors, switch to the hard-floor mode and use the appropriate cleaning path. Avoid using the SteamVac on hardwood floors, as it may cause damage. Always move slowly and overlap cleaning paths for thorough coverage. Follow the manual’s surface-specific guidelines to ensure safe and effective cleaning results across all areas.

Maintenance and Care

Regularly clean the machine, store it properly, and maintain filters to ensure optimal performance and longevity of the Hoover SteamVac SpinScrub.

5.1 Regular Cleaning of the Machine

Regular cleaning of the Hoover SteamVac SpinScrub is essential for maintaining its performance and longevity. After each use, empty the dirt tank and rinse it thoroughly with warm water. Clean or replace filters as needed to ensure proper suction and prevent clogs. Wipe down the exterior and interior surfaces with a damp cloth to remove dirt and debris. Check the brushes for hair or debris and remove any blockages. Allow all parts to dry completely before storing the machine. Regular maintenance helps prevent mold growth and keeps the cleaner functioning efficiently. Refer to the manual for specific cleaning instructions tailored to your model.

5.2 Storing the SteamVac SpinScrub

Proper storage of the Hoover SteamVac SpinScrub is crucial for maintaining its condition and longevity. After cleaning, ensure the machine and all accessories are completely dry to prevent mold or mildew growth. Store the cleaner in a cool, dry place, away from direct sunlight and moisture. Avoid storing it in areas where temperatures may fluctuate excessively. Before storage, check that all tanks, such as the clean solution tank, are empty and rinsed; Secure the power cord neatly to prevent tangling, and store any detachable parts like brushes or upholstery tools in a designated area. Regularly inspect stored components for damage or blockages before reuse.

5.3 Replacing or Cleaning Filters

Regular maintenance of the filters in your Hoover SteamVac SpinScrub is essential for optimal performance and odor control. Check and clean the filters after each use to ensure proper suction and efficiency. Rinse reusable filters with warm water and mild detergent, then allow them to air dry completely before reinstalling. Replace filters every 1-2 months or as indicated in the manual, especially if they become visibly soiled or damaged. For the best results, always use genuine Hoover replacement filters. Regular filter maintenance prevents clogs, reduces odors, and extends the lifespan of your cleaner. Refer to the manual for specific filter locations and replacement instructions.

Troubleshooting Common Issues

Troubleshooting common issues with the Hoover SteamVac SpinScrub helps maintain performance. Refer to the manual for solutions to problems like reduced suction, brush malfunctions, or water leaks.

6.1 No suction or reduced performance

If the Hoover SteamVac SpinScrub experiences no suction or reduced performance, check for blockages in the hose, wand, or cleaner head. Ensure the dirty water tank is empty, as a full tank can restrict airflow; Regularly clean or replace filters, as clogged filters may reduce suction power. Additionally, inspect the belts and brushes for damage or debris buildup. Refer to the manual for guidance on disassembling and cleaning internal components. If issues persist, consider checking for worn or loose connections in the vacuum system. Proper maintenance and regular inspection can help restore optimal performance and extend the lifespan of the cleaner.

6.2 Issues with the SpinScrub Brushes

If the SpinScrub brushes on your Hoover SteamVac SpinScrub are not rotating or are damaged, first check for tangled hair or debris wrapped around the brush assembly. Detach the brush block and clean it thoroughly with warm water and mild detergent. For worn or damaged brushes, replace them with genuine Hoover parts. Ensure the brushes are properly installed and aligned to maintain optimal cleaning performance. Regularly inspect and maintain the brushes to prevent clogging and extend their lifespan. Refer to the manual for specific guidance on brush replacement and maintenance to keep your cleaner functioning effectively.

6.3 Leaks or Water Issues

If your Hoover SteamVac SpinScrub is leaking or experiencing water issues, check the clean solution tank and dirty water tank for proper securement. Ensure all connections, such as hoses and gaskets, are tight and free from damage. Blockages in the system, like clogged filters or kinked hoses, can also cause water to leak. Regularly inspect and clean filters to maintain proper water flow. Additionally, verify that the correct Hoover-recommended cleaning solution is used, as improper detergents may cause issues. If leaks persist, empty the tanks and allow the machine to dry before further use. For unresolved problems, consult the manual or contact Hoover customer support for assistance.

Environmental Considerations

Using eco-friendly cleaning solutions and properly disposing of waste helps reduce environmental impact. Always follow guidelines for water usage and detergent disposal to minimize harm to the environment.

7.1 Eco-Friendly Cleaning Practices

Adopt eco-friendly practices when using the Hoover SteamVac SpinScrub. Opt for biodegradable cleaning solutions to minimize environmental impact. Always follow recommended detergent dosages to avoid excess chemical use. Ensure proper disposal of cleaning waste and empty tanks responsibly. For hard floors, use water-only cleaning when possible to reduce chemical usage. Regularly maintain the machine to optimize efficiency and reduce energy consumption. Consider recycling old or damaged parts when upgrading. By adhering to these practices, you contribute to a more sustainable cleaning routine while ensuring effective results for your carpets and upholstery.

7.2 Proper Disposal of Cleaning Solutions

Proper disposal of cleaning solutions used with the Hoover SteamVac SpinScrub is essential for environmental protection. Always check local regulations for disposal guidelines. Do not pour cleaning solutions down drains, as they may harm water systems. Instead, take them to designated hazardous waste facilities. Store solutions in sealed containers to prevent accidental spills. Mixed cleaning solutions should be treated as hazardous waste and disposed of accordingly. After cleaning, rinse the solution tank thoroughly and dispose of the rinse water responsibly. Encourage recycling of empty cleaning solution bottles whenever possible. By following these steps, you help protect the environment and ensure safe disposal practices for your cleaning routine.

The Hoover SteamVac SpinScrub is an effective cleaning solution for carpets and surfaces. Proper use and maintenance ensure optimal performance. For further support, refer to the official manual or Hoover’s customer service.

8.1 Summary of Key Points

The Hoover SteamVac SpinScrub is a versatile and efficient cleaning tool designed for deep carpet and surface cleaning. Its SpinScrub technology ensures thorough stain removal, while its adjustable settings cater to various surfaces. Proper assembly and maintenance, as outlined in the manual, are crucial for optimal performance. Always follow safety guidelines to avoid electrical hazards or damage. Regular cleaning of filters and tanks extends the machine’s lifespan. For additional support, refer to the official Hoover manual or contact customer service. By adhering to these guidelines, users can achieve professional-grade cleaning results while maintaining the durability of their SteamVac SpinScrub cleaner.

8.2 Where to Find Additional Support or Manuals

For additional support or manuals, visit the official Hoover website or authorized retailers like Amazon. ManualsLib and similar platforms also offer free PDF downloads of the Hoover SteamVac SpinScrub manual. Ensure to verify the model number for the correct guide. Retailers often include links to manuals on product pages. If the manual was lost, contact Hoover customer support directly for assistance. Online forums and communities may provide troubleshooting tips shared by other users. Always refer to official sources to avoid outdated or incorrect information.