Instructor manuals are comprehensive guides designed to help educators deliver structured and effective training․ They provide detailed lesson plans, updated guidelines, and essential resources for successful course delivery․

1․1 Definition and Purpose of Instructor Manuals

Instructor manuals are comprehensive documents designed to guide educators in delivering structured and effective training programs․ They serve as central resources for instructors, outlining teaching methods, course materials, and best practices to ensure consistency and quality in training․ These manuals are tailored to specific disciplines, providing detailed frameworks for lesson planning, course setup, and evaluation․ Their primary purpose is to empower instructors with the tools and knowledge needed to create engaging and impactful learning experiences․ By standardizing training processes, instructor manuals help ensure that participants receive a uniform and high-quality education, regardless of the instructor or location․ They are essential for maintaining adherence to organizational standards and promoting continuous improvement in training environments․

1․2 Importance of Instructor Manuals in Training

Instructor manuals play a vital role in ensuring the consistency and quality of training programs․ They provide instructors with a clear framework, enabling them to deliver courses efficiently and effectively․ By standardizing teaching methods and materials, these manuals help maintain uniformity across different training sessions and locations․ They also serve as a reference for instructors to stay updated on the latest guidelines and best practices․ Additionally, instructor manuals enhance the organization and structure of training, making it easier for educators to prepare and conduct sessions․ Their importance lies in their ability to support instructors in creating engaging and impactful learning experiences, ultimately contributing to better learner outcomes and adherence to organizational standards․

Features of Instructor Manuals

Instructor manuals feature structured content, including lesson plans, updated guidelines, and training techniques․ They often include digital access, discipline-specific tools, and resources to enhance teaching effectiveness and consistency․

2․1 Standard Elements of an Instructor Manual

An instructor manual typically includes a table of contents, detailed lesson plans, learning objectives, assessment methods, and instructor notes․ It also contains teaching strategies, activity descriptions, and resources like worksheets or multimedia links․ Many manuals incorporate case studies, best practices, and compliance guidelines to ensure consistency․ They often feature appendices with additional materials such as answer keys, checklists, and forms․ These elements help instructors deliver training effectively, ensuring that learners achieve the desired outcomes․ The structure and content are designed to support both novice and experienced educators, making the manual a versatile tool for various teaching environments and disciplines․

2․2 Digital vs․ Print Instructor Manuals

Instructor manuals are available in both digital and print formats, each offering unique advantages․ Digital manuals provide easy access, regular updates, and interactive features like multimedia content and hyperlinks․ They are eco-friendly and can be shared effortlessly among instructors․ Print manuals, while less flexible, offer a tactile experience and are often preferred for quick reference during training sessions․ Both formats cater to different learning preferences, with digital manuals being ideal for tech-savvy educators and print manuals suiting those who value physical materials․ Many organizations, like the American Heart Association, offer both options to accommodate diverse instructor needs and ensure accessibility․

2․3 Discipline-Specific Features in Instructor Manuals

Instructor manuals are often tailored to specific disciplines, ensuring relevance and effectiveness․ For example, PADI Instructor Manuals include detailed lesson plans and forms for diving courses, while AHA manuals incorporate updated medical guidelines for CPR and ECC training․ Flight Instructor Manuals focus on aviation techniques and practical session guidance․ Discipline-specific features ensure instructors can deliver specialized content accurately․ These manuals include resources like checklists, multimedia content, and updated scientific recommendations, making them indispensable for educators in their respective fields․ Such customization enhances the quality of training and prepares professionals for real-world challenges in their discipline․

Course Outlines and Lesson Plans

Instructor manuals provide structured course outlines and detailed lesson plans, ensuring consistent and effective training delivery․ They include key elements like timelines, objectives, and activities for comprehensive coverage․

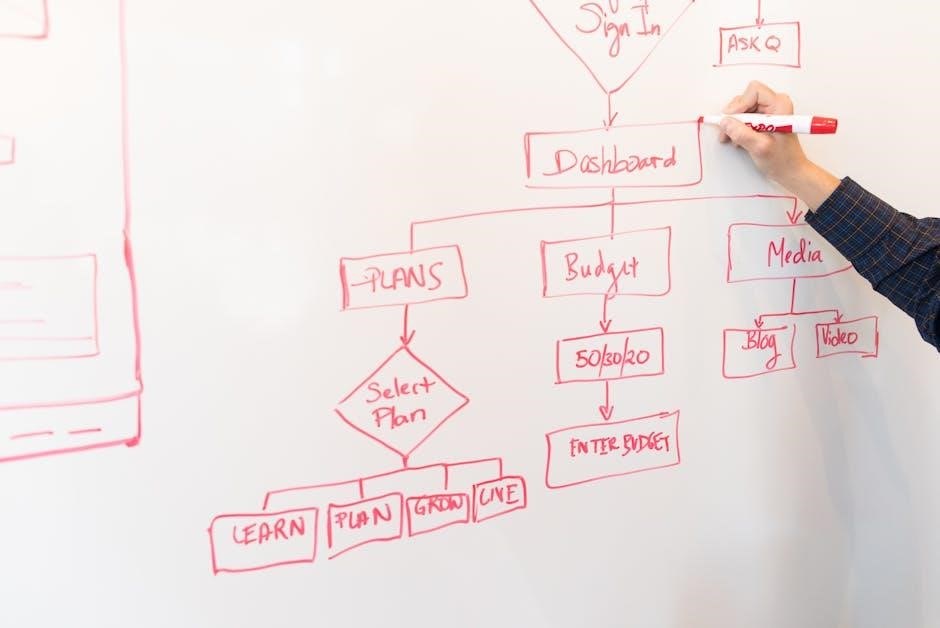

3․1 Structuring Effective Course Outlines

Effective course outlines are essential for organized and goal-oriented training․ They provide a clear framework, including timelines, objectives, and activities, ensuring all topics are covered comprehensively․ A well-structured outline helps instructors deliver content logically, engaging participants and ensuring learning goals are met․ It also allows for flexibility, adapting to diverse learning styles and pacing․ Key elements include specific lesson objectives, detailed timelines, and interactive activities․ This structure ensures consistency and alignment with training standards, making the learning experience cohesive and impactful for participants․

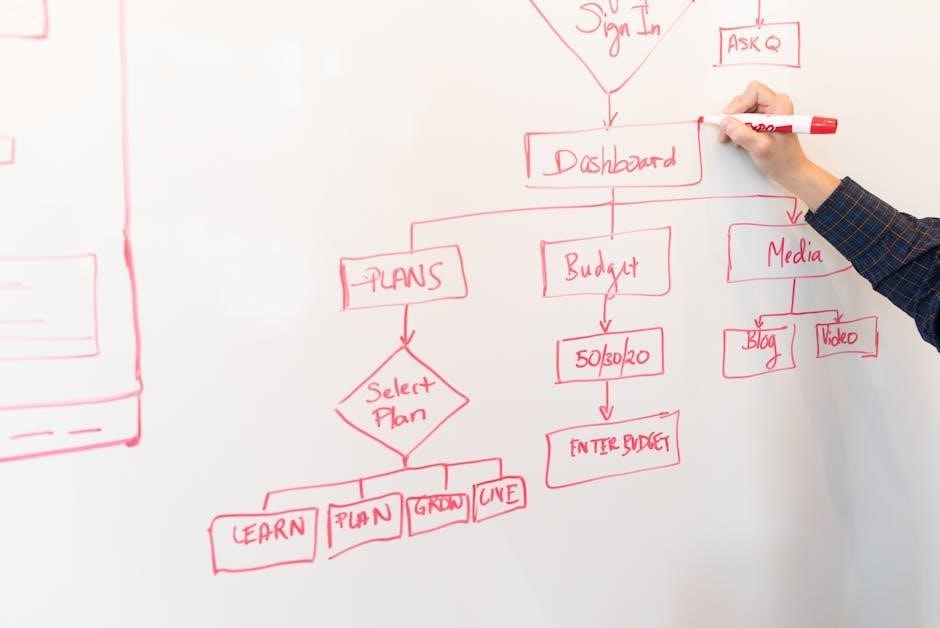

3․2 Creating Engaging Lesson Plans

Engaging lesson plans are vital for capturing participants’ interest and ensuring effective learning․ They should include clear objectives, interactive activities, and assessments to measure understanding․ Incorporating a mix of auditory, visual, and kinesthetic elements caters to diverse learning styles․ Real-world examples and practical exercises enhance relevance and retention․ Instructors should also incorporate flexibility, allowing for adjustments based on participant engagement and pace․ Technology integration, such as multimedia resources, can further enrich the learning experience․ Well-structured lesson plans not only promote active participation but also ensure alignment with course goals, making training sessions both informative and memorable for learners․

Training Techniques and Strategies

Effective training techniques involve combining auditory, visual, and kinesthetic methods to enhance learning․ These strategies ensure diverse learning styles are addressed, improving overall knowledge retention and engagement․

4․1 Combining Auditory, Visual, and Kinesthetic Learning

Effective instruction combines auditory, visual, and kinesthetic learning techniques to cater to diverse learning styles․ Auditory methods include lectures and discussions, while visual approaches use diagrams, videos, and slides․ Kinesthetic learning involves hands-on activities, such as simulations or practical exercises․ This multi-sensory approach enhances retention, as it engages different parts of the brain․ For example, instructors can pair verbal explanations with visual aids and follow up with interactive tasks․ This strategy ensures that all learners, regardless of their preferred style, can absorb and apply the material effectively․ Integrating these methods creates a dynamic and inclusive training environment, fostering better understanding and participation․

4․2 Best Practices for Delivering Instructor-Led Training

Effective instructor-led training requires a structured approach to ensure learner engagement and knowledge retention․ Start with clear, well-defined objectives and use a variety of teaching methods to cater to different learning styles․ Encourage active participation through discussions, group activities, and hands-on exercises․ Provide real-world examples and case studies to illustrate key concepts, making the content relatable and practical․ Use visual aids like slides, videos, and diagrams to enhance understanding․ Offer constructive feedback and encourage questions to foster a collaborative learning environment․ Stay updated with the latest industry trends and incorporate new techniques to keep the training relevant and engaging․ Regularly assess the effectiveness of your delivery to refine and improve future sessions․

Resources for Instructors

Instructors can access program administration manuals, online platforms, and discipline-specific guides for support․ These resources include lesson plans, updated guidelines, and tools for effective training delivery․

5․1 Accessing Program Administration Manuals

Program administration manuals are essential resources for instructors, providing detailed guidelines and frameworks for effective training delivery․ These manuals are typically accessible through official websites or platforms associated with specific training programs, such as the American Heart Association (AHA) Instructor Network․ They often include updated scientific guidelines, lesson plans, and tools to support instructors in teaching various courses․ For example, the AHA ACLS Instructor Manual offers essential information for teaching advanced cardiovascular life support․ Accessing these manuals ensures instructors stay current with best practices and deliver high-quality training․ They are indispensable for maintaining consistency and excellence in educational programs․

5․2 Utilizing Online Platforms for Instructor Support

Online platforms provide instructors with valuable resources and tools to enhance their teaching effectiveness․ Websites like the American Heart Association Instructor Network and PADI Pros Site offer exclusive access to updated course materials, training guides, and program administration manuals․ These platforms often include digital libraries, interactive training tools, and forums for instructor collaboration․ They enable instructors to stay current with the latest guidelines, share best practices, and access support materials․ Online platforms also facilitate seamless communication and resource sharing among instructors, fostering a sense of community and continuous improvement in training delivery․ Utilizing these platforms ensures instructors are well-equipped to provide high-quality, engaging education․

Updates and Revisions in Instructor Manuals

Instructor manuals are regularly updated to reflect new guidelines, scientific advancements, and training methodologies․ Updates ensure instructors deliver current, evidence-based content effectively․

6․1 Incorporating New Guidelines and Science

Instructor manuals are periodically updated to incorporate new guidelines and scientific advancements, ensuring training remains evidence-based and aligned with industry standards․ These updates often include revised lesson plans, updated protocols, and new teaching strategies․ For example, the American Heart Association (AHA) updates its manuals with the latest CPR and ECC guidelines, while PADI integrates new diving science and safety protocols․ Such revisions help instructors deliver cutting-edge training, enhancing learner outcomes․ Regular updates also ensure compliance with regulatory changes and emerging best practices, making instructor manuals indispensable tools for effective and modern training delivery․

Role of the Instructor

Instructors are responsible for planning, delivering, and assessing training effectively․ They ensure learners master skills and knowledge by following manual guidelines and staying updated with new developments․

7․1 Responsibilities of an Effective Instructor

An effective instructor is responsible for preparing and delivering well-structured lessons, ensuring alignment with the instructor manual․ They must stay updated on guidelines and best practices, adapting content to meet learner needs․ Instructors should create an engaging environment, combining auditory, visual, and kinesthetic learning methods․ They are also tasked with assessing student progress, providing constructive feedback, and ensuring compliance with training standards․ Effective instructors foster active participation, address questions, and maintain a safe and inclusive learning atmosphere․ Continuous improvement through self-reflection and seeking feedback is essential to enhance teaching strategies and outcomes․ Ultimately, instructors play a critical role in ensuring learners achieve the desired skills and knowledge effectively․

Legal and Ethical Considerations

Instructor manuals must comply with legal standards, ensuring copyright laws are respected and training materials are accurate․ Ethical practices include maintaining learner privacy and avoiding bias․

8․1 Ensuring Compliance with Training Standards

Instructor manuals play a crucial role in ensuring compliance with established training standards․ They provide clear guidelines to help instructors deliver courses that align with legal and regulatory requirements․

By adhering to these standards, instructors can ensure that training materials are accurate, up-to-date, and free from bias․ Regular updates to manuals, such as those incorporating new scientific guidelines, further reinforce compliance and ethical training practices․

Case Studies and Real-World Applications

Instructor manuals provide real-world applications through case studies, such as the AHA Instructor Network and PADI Guide to Teaching, ensuring effective training and compliance․

9․1 Successful Implementation of Instructor Manual Guidelines

Successful implementation of instructor manual guidelines ensures effective training delivery and learner engagement․ Real-world applications, such as the AHA Instructor Network and PADI Guide to Teaching, demonstrate how manuals are used to structure courses, update guidelines, and provide essential resources․ For instance, the BLS Instructor Manual incorporates new science for CPR training, while the Flight Instructor’s Manual offers practical guidance for aviation education․ These case studies highlight the importance of adhering to manual guidelines to ensure compliance, consistency, and high-quality training outcomes across disciplines․ By leveraging these resources, instructors can deliver structured, engaging, and impactful learning experiences tailored to their specific fields․

Future Trends in Instructor Manuals

Future trends include AI integration, virtual reality, and interactive content․ Manuals will adapt to digital platforms, offering real-time analytics and personalized learning experiences for instructors and trainees․

10․1 Integration of AI and Technology in Training

The integration of AI and technology into instructor manuals is revolutionizing training processes․ AI-driven tools now enable personalized learning experiences, real-time feedback, and adaptive assessments․ Virtual reality (VR) and augmented reality (AR) simulations are being incorporated to create immersive training environments; Data analytics within digital manuals allow instructors to track learner progress and identify knowledge gaps․ Automated grading systems and intelligent tutoring platforms enhance efficiency and accuracy․ AI-powered chatbots, like ChatGPT, are being used to provide instant support and resources for instructors․ These advancements not only modernize training materials but also make them more accessible and engaging for diverse learners․ Technology is reshaping the future of instructor manuals, ensuring they remain relevant and effective in a rapidly evolving educational landscape․